Checking out the Benefits of Making Use Of Bulk Containers in Modern Supply Chains

The usage of mass containers in modern-day supply chains offers a series of advantages that deserve mindful factor to consider. These containers can cause substantial cost financial savings while enhancing logistical efficiency. They also play a crucial role in reducing packaging waste and boosting storage space services. As markets significantly focus on sustainability, the potential influence of bulk containers becomes much more pertinent. What certain benefits can be realized by embracing this method?

Expense Savings With Bulk Handling

Mass handling offers substantial price financial savings for services within contemporary supply chains. By utilizing bulk containers, firms can lower packaging prices considerably, as fewer products are required for transport and storage space. This decrease in product packaging not just decreases expenditures yet also decreases waste, straightening with sustainability objectives. Furthermore, mass handling makes it possible for more reliable transport, as bigger quantities can be shipped in less journeys, resulting in reduced freight expenses.

Labor expenses additionally see a decrease; bulk materials normally call for less manual handling, enabling team to focus on other value-added jobs. The structured storage space of mass containers maximizes storehouse area, leading to potential savings in rental or functional prices - used plastic containers. On the whole, implementing mass handling techniques can greatly boost a company's profits, making it an appealing alternative for organizations seeking to improve their expense effectiveness in a competitive market

Boosted Effectiveness in Logistics

While typical supply chain methods usually involve fragmented processes, the combination of mass containers significantly improves logistics effectiveness. These containers promote the structured movement of items, lowering dealing with times and decreasing the demand for numerous transfers. By consolidating materials right into fewer shipments, companies can maximize transportation paths and lower overall freight prices.

The boosted presence offered by bulk logistics allows real-time tracking of shipments, enabling supply chain supervisors to react quickly to any interruptions. In general, the fostering of mass containers changes logistics operations, cultivating an extra receptive and dexterous supply chain that meets the needs of contemporary commerce.

Decrease of Product Packaging Waste

As firms look for to enhance sustainability in their procedures, making use of bulk containers plays a crucial role in reducing product packaging waste. Traditional product packaging methods usually include multiple layers, leading to significant waste, both in products and disposal. By making use of mass containers, businesses can significantly lessen the quantity of packaging needed, as these containers are made to be recycled and recycled. This shift not only reduces the quantity of single-use product packaging sent out to garbage dumps yet also lowers the carbon impact related to production and delivering product packaging products. Additionally, mass containers help with much more reliable loading procedures, enabling a better quantity of products to be delivered at once, thus decreasing the requirement for excessive packaging. Ultimately, embracing mass containers causes an extra lasting supply chain, aligning functional exercise with ecological duty while likewise read more potentially decreasing prices linked with packaging waste monitoring.

Improved Storage Solutions

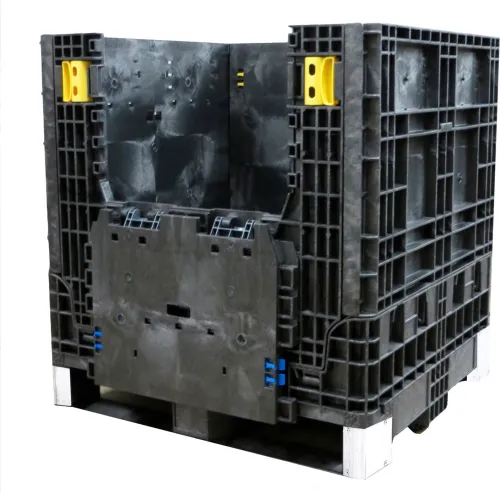

Effective storage remedies are necessary for maximizing supply chain efficiency, particularly when mass containers are employed. These containers take full advantage of space usage, enabling greater thickness storage space. Their consistent dimensions enable stacking, which reduces the impact needed in stockrooms and distribution centers. This company not only improves accessibility however additionally improves supply management.

Furthermore, mass containers can be developed to accommodate different materials, from liquids to solids, thereby offering adaptability in storage space options. Their durable building assurances toughness, decreasing the danger of damages during handling and transport. Subsequently, companies can experience fewer disruptions and lower replacement prices.

Moreover, the standardization of bulk containers helps with simpler combination into automated storage space and access systems, better enhancing functional efficiency. In conclusion, the fostering of bulk containers leads to boosted storage remedies that support structured procedures and contribute positively to total supply chain efficiency.

Advertising Sustainability in Supply Chains

Advertising sustainability in supply chains has actually come to be an essential emphasis for organizations seeking to reduce their environmental impact. The fostering of mass containers acts as a critical technique for improving sustainability initiatives. These containers, made for efficient storage space and transport, significantly lower product packaging waste compared to traditional packaging methods. By utilizing durable products, mass containers can be reused numerous times, further lowering the demand for single-use packaging.

Moreover, mass containers maximize logistics by making best use of space utilization throughout transportation, thus lowering carbon emissions related to delivery. Companies can additionally streamline their supply chain procedures, which adds to decreasing power usage. Furthermore, companies that focus on sustainability often boost their brand name track record, attracting eco aware customers. In general, integrating mass containers right into supply chains not just promotes eco-friendly obligation but additionally promotes operational performance, showing a detailed method to lasting business methods.

Often Asked Inquiries

What Types of Products Are Ideal Suited for Mass Containers?

Products ideal suited for bulk containers consist of grains, chemicals, liquids, and big parts. These products take advantage of effective storage space, transport, and reduced packaging waste, ultimately improving functional performance and cost-effectiveness within supply chain processes.

Just How Do Bulk Containers Influence Inventory Monitoring Practices?

Bulk containers improve supply management by decreasing handling times and enhancing storage space. They enhance visibility of stock levels, simplify monitoring, and promote even more accurate forecasting, inevitably resulting in improved effectiveness and minimized operational prices.

Exist Certain Industries That Advantage Most From Bulk Containers?

Particular industries, such as agriculture, chemicals, and food processing, advantage most from bulk containers. refurbished bulk containers. These markets make use of bulk containers to boost efficiency, reduce expenses, and boost logistics, eventually simplifying their supply chain procedures greatly

What Are the Safety Considerations When Utilizing Mass Containers?

Security factors to consider when using mass containers consist of guaranteeing structural honesty, correct handling methods, safe loading and discharging processes, normal assessments for leaks or damages, and compliance with pertinent laws to mitigate dangers throughout transport and storage.

Just How Can Companies Transition to Mass Container Equipments Properly?

Business can efficiently change to bulk container systems by examining current logistics, educating staff, progressively carrying out the brand-new system, reviewing vendor capacities, and continuously keeping an eye on efficiency to assure efficiency and safety throughout the procedure. (used collapsible containers)

The use of bulk containers in modern-day supply chains presents an array of advantages that are entitled to careful consideration. By making use of bulk containers, companies can minimize packaging expenses considerably, as fewer materials are needed for transportation and storage space. While traditional supply chain techniques commonly entail fragmented procedures, the assimilation of mass containers substantially enhances logistics performance. By making use of bulk containers, businesses can especially minimize the quantity of product packaging called for, as these containers are designed to be recycled and reused. Reliable storage remedies are essential for maximizing supply chain effectiveness, especially when mass containers are used.